Compaction Related Lab Testing

Compaction

Supported Test Methods

Standard | Description |

|---|---|

ASTM D 1557-07 | Laboratory compaction characteristics of soil using modified effort |

BS1377-4:1990:3 | Determination of dry density/moisture content relationship |

Input

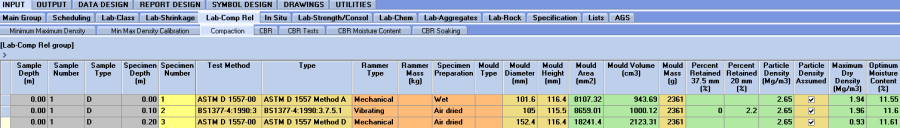

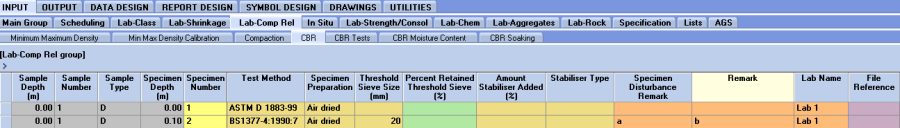

Lab-Comp Rel | Compaction

To calculate the particle size distribution of a specimen, you must first select the standard from the Test_Method field on the Compaction (upper) table that the specimen is being tested against. Once selected, the necessary data entry fields will be automatically highlighted to assist you in entering the relevant data in the Compaction (upper) table for the selected test method.

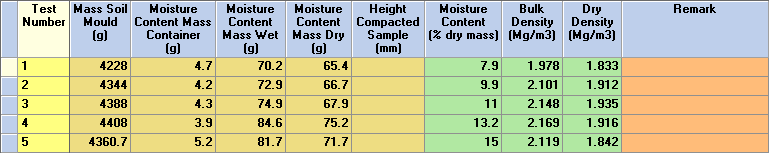

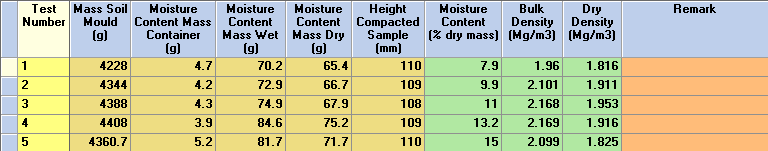

Enter the test data in the data entry fields on the Compaction (lower) table for each test and when you change table or select save, the values will be calculated automatically and the result will be displayed in the calculated fields. The Bulk_Density field on the Compaction (lower) table will be calculated by the following equation for the ASTM D 1557-00 method or for the BS1377-4:1990:3 methods:

ρ=(m2- m1)/V

If the height of a compacted sample is recorded the Bulk_Density field on the Compaction (lower) table will be calculated by the following equation for the ASTM D 1557-00 method or for the BS1377-4:1990:3 method: ρ= ((m2-m1)/Ah)*1000

If a particle density test has been recorded on the Particle_Density / Specific_Gravity Table for the current specimen being tested, then that particle density result will be written to the Particle_Density field on the Compaction table. If however you want to enter an assumed particle density value, check the box in the Particle_Density_Assumed field and enter the assumed particle density value in the Particle_Density field.

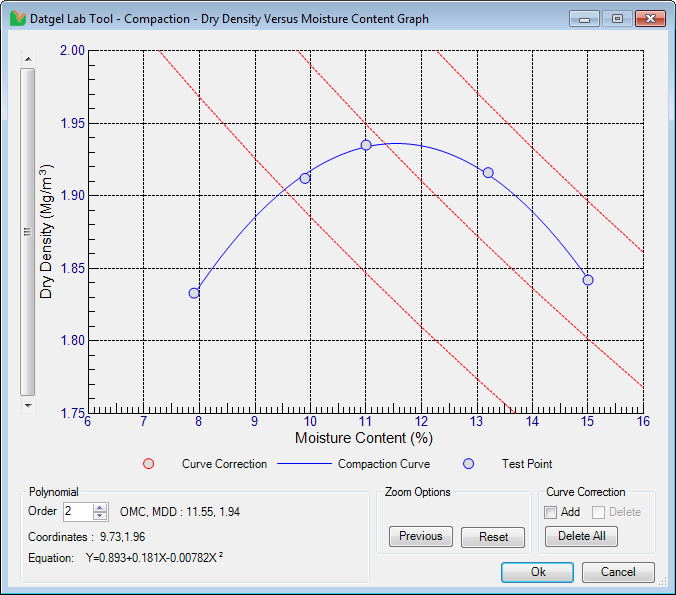

Maximum Dry Density & Optimum Moisture Content

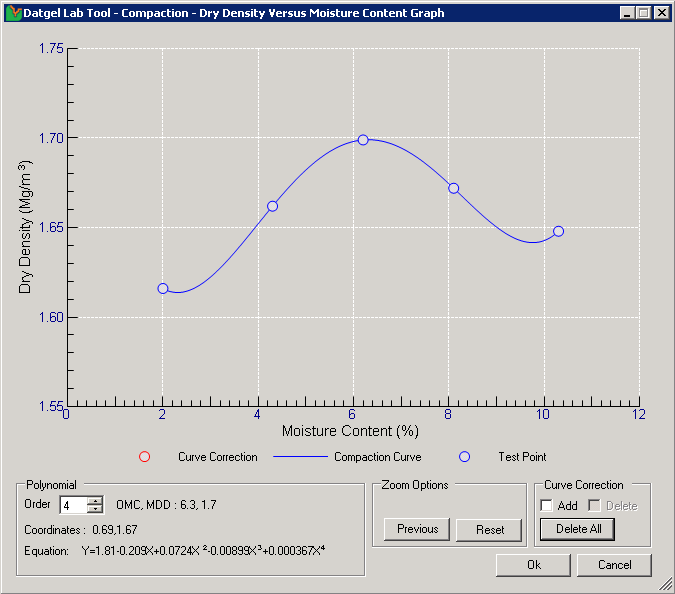

To determine the maximum dry density value from the compaction plot, select Add-Ins > Datgel Lab and In Situ Tool > Compaction Graph to launch the compaction curve plot based on the recorded test data.

The initial plot displayed by the Datgel Lab and In Situ Tool is based on the test data entered into you gINT database and can be manually refined should it be necessary.

To zoom in to an area of interest on the plot, you need to draw a window around the area that you wish to zoom into. To draw the window, move the mouse pointer to a position on the plot that you want to define as a corner of the zoom window and whilst holding the left mouse button down, move the mouse pointer to define the zoom window. When you release the left mouse button, the view will zoom into the area you have just defined.

To return to the previous view select the Previous button and to revert to the initial plot view select Reset.

The polynomial order of the equation can be increased or decreased by clicking on the up or down arrow for the Polynomial Order box.

Sometimes the automatically fitted curve will have curls and extreme curves, as shown in the next figure – Example Uncorrected Compaction Curve Plot.

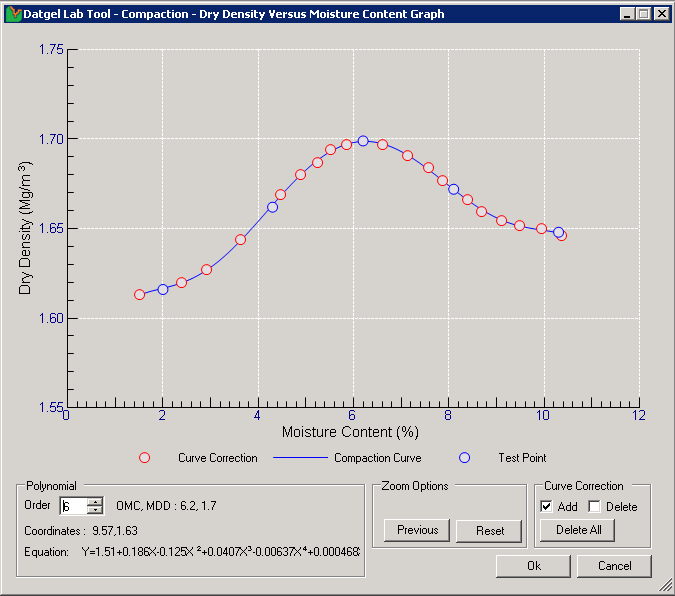

To remedy this, you can add Curve Correction points by first checking the Add check box, and then clicking on the graph in the required location. We have found that tracing the required curve with Correction Points, and then increasing the Polynomial Order is often successful.

To remove an individually added Curve Correction point, check the Delete box and select the point that you wish to delete. To remove all the Curve Correction points, select the Delete All button.

If you are satisfied with the defined compaction curve, click Ok and you will be returned to the gINT Input screen and you will see that the Maximum_Dry_Density and Optimum_Moisture_Content fields have been populated based on the compaction curve graph. The equation, polynomial order and the coefficients of the curve are written to the Curve_Formula, Curve_Order and the Curve_Coefficients fields for future reference.

If you are not satisfied with the defined compaction curve, click Cancel.

Output

- Graph Report | L CR COMPACTION

CBR

Supported Test Methods

Standard | Description |

|---|---|

ASTM D 1883-07e2 | CBR (California Bearing Ratio) of laboratory compacted soils |

BS1377-4:1990:7 | Determination of California Bearing Ratio (CBR) |

Input

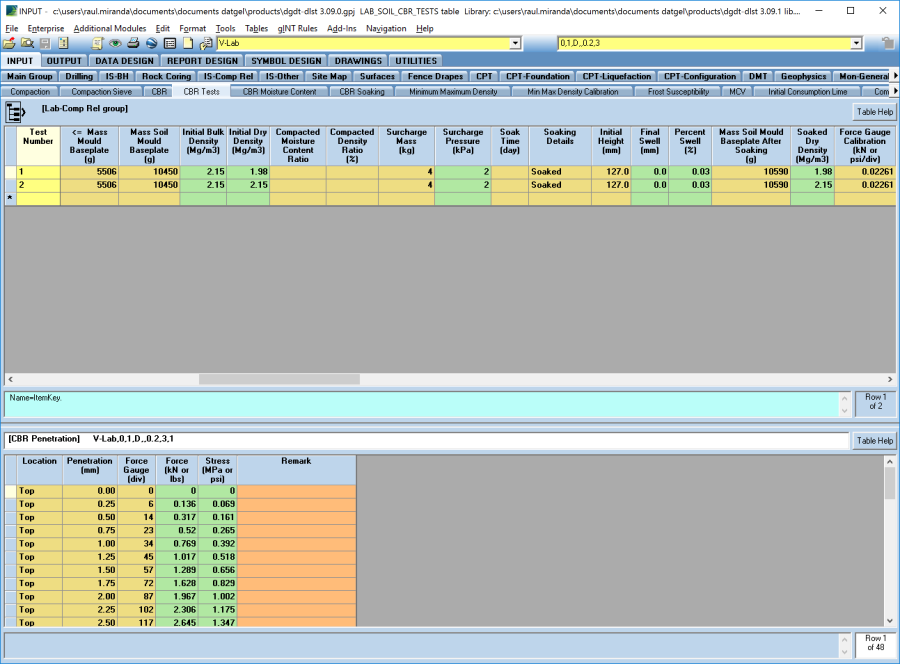

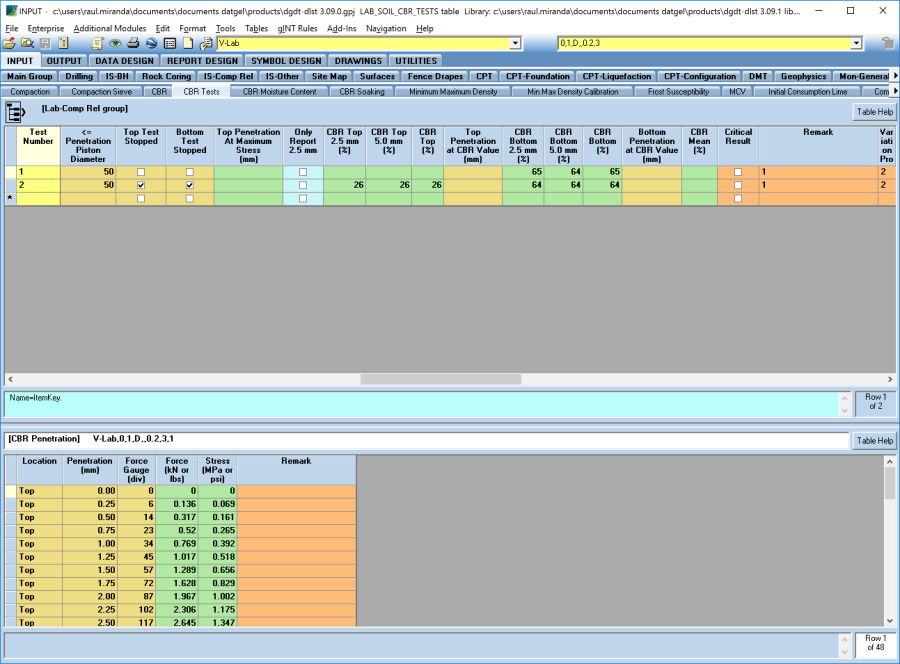

Lab-Comp Rel | CBR

To calculate the CBR Values of a specimen, you must first select the standard from the Test_Method field on the CBR table that the specimen is being tested against. Once selected, the necessary data entry fields will be automatically highlighted to assist you in entering the relevant data in the CBR Tests table for the selected test method.

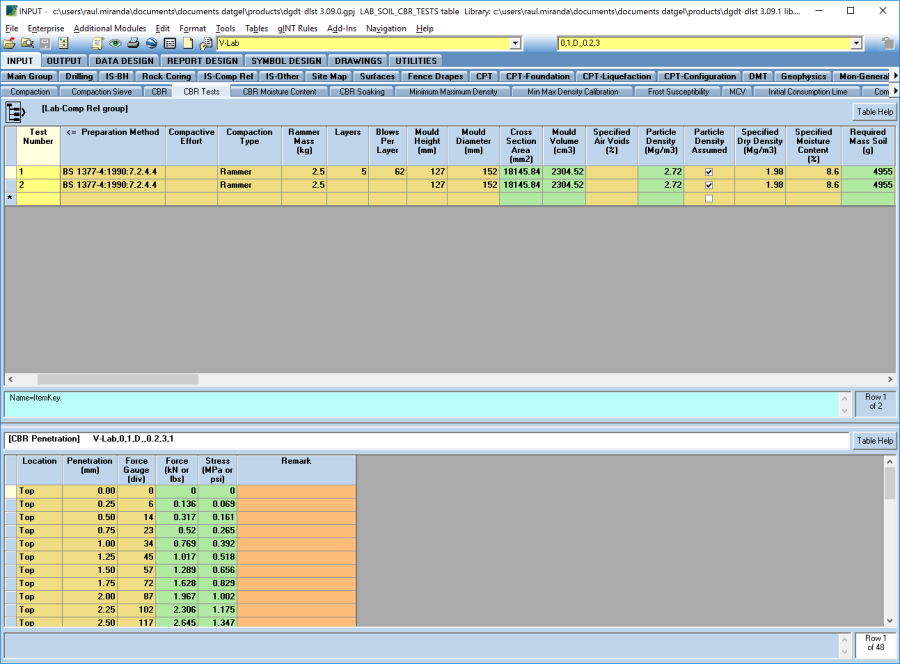

On the CBR_Tests (upper) table for each stage, define the preparation method used and the associated parameters. When you move to the CBR_ests (lower) table or select save, the Cross_Section_Area and Mould_Volume fields will be calculated.

If a particle density test has been recorded on the Particle_Density / Specific_Gravity Table for the current specimen being tested, then that particle density result will be written to the Particle_Density field on the CBR_Tests table. If however you want to enter an assumed particle density value, check the box in the Particle Density Assumed field and enter the assumed particle density value in the Particle_Density field.

Enter the CBR test data in the data entry fields on the CBR_Tests (lower) table for each penetration test and when you change table or select save, the values will be calculated automatically and the result will be displayed in the calculated fields.

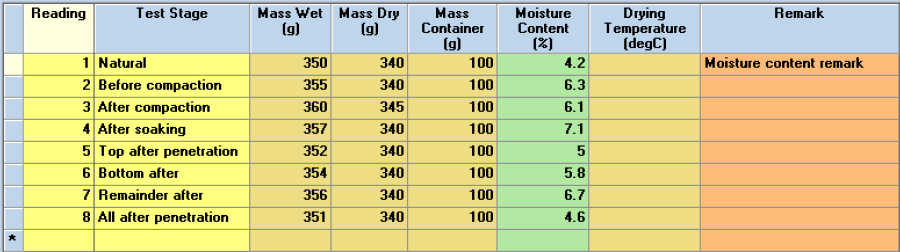

CBR Moisture Content Calculations

Select the CBR Moisture_Content table to storage and calculate the moisture content values determined in for each CBR test.

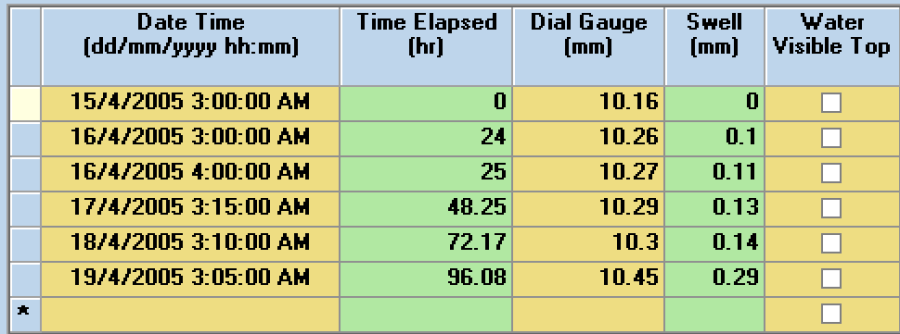

CBR Soaking

Select the CBR_Soaking table to storage and calculate the swell values determined in for each CBR test.

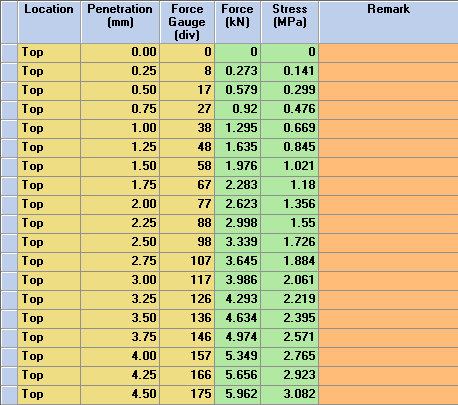

CBR Penetration Calculations

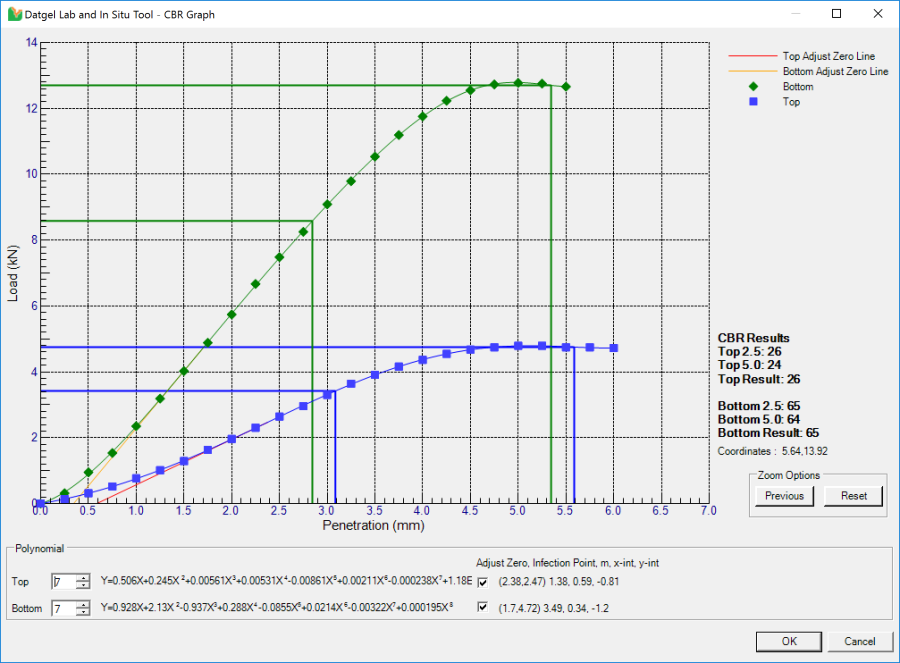

To determine the CBR values from the CBR chart, select Add-Ins > Datgel Lab and In Situ Tool > CBR Graph to launch the CBR plot based on the recorded test data.

The initial plot displayed by the Datgel Lab and In Situ Tool is based on the test data entered into you gINT database and can be manually refined should it be necessary.

To zoom in to an area of interest on the plot, you need to draw a window around the area that you wish to zoom into. To draw the window, move the mouse pointer to a position on the plot that you want to define as a corner of the zoom window and whilst holding the left mouse button down, move the mouse pointer to define the zoom window. When you release the left mouse button, the view will zoom into the area you have just defined.

To return to the previous view select the Previous button and to revert to the initial plot view select Reset.

The polynomial order of the equation can be increased or decreased by clicking on the up or down arrow for the Polynomial Order box.

If you are satisfied with the defined CBR Results, click Ok and you will be returned to the gINT Input screen and you will see that have been populated based on the curve. The equation, polynomial order and the coefficients of the curve are written to a field for future reference.

If you are not satisfied with the defined compaction curve, click Cancel.

Output

- Graph Report | L CR CBR PENETRATION

- Graph Report | L CR CBR PENETRATION MULTI

- Graph Report | L CR CBR SWELLING

- Graph Report | L CR CBR VERSUS DRY DENSITY

- Histogram Report | A L CR CBR

Minimum and Maximum Density - Vibratory Table

Minimum and Maximum Density Calibration

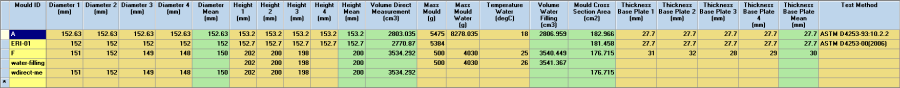

Lab-Comp Rel | Min Max Density Calibration

Complete the data entry fields and enter any other associated metadata as required. The value entered in the Mould_ID field will then be used in the lookup list in the Mould_ID field on the Minimum_Maximum_Density_Readings table.

The calculations use Volume_Water_Filling in precedence over Volume_Direct_Measurement. If Temperature_Water is provided, then the correction factors in ASTM 4254-00 Table 2 is applied.

Supported Test Methods

Standard | Description |

|---|---|

Minimum Density |

|

ASTM D 4254-00 A | Minimum Index Density and Unit Weight of Soils - Method A |

ASTM D 4254-00 B | Minimum Index Density and Unit Weight of Soils - Method B |

ASTM D 4254-00 C | Minimum Index Density and Unit Weight of Soils - Method C |

Maximum Density |

|

ASTM D 4253-93 1A | Method 1A - Maximum index density using oven dried soil, electromagnetic, vertical vibrating table |

ASTM D 4253-93 1B | Method 1B - Maximum index density using wet soil, electromagnetic, vertical vibrating table |

ASTM D 4253-93 2A | Method 2A - Maximum index density using oven dried soil, eccentric or cam driven, vertical vibrating table |

ASTM D 4253-93 2B | Method 2B - Maximum index density using wet soil, eccentric or cam driven, vertical vibrating table |

Input

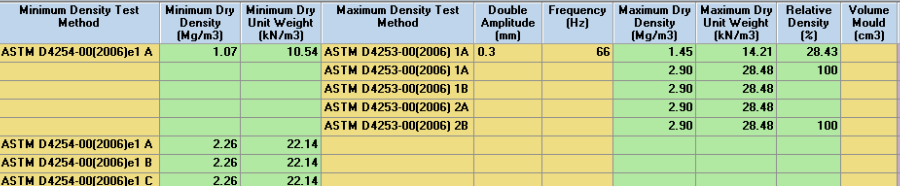

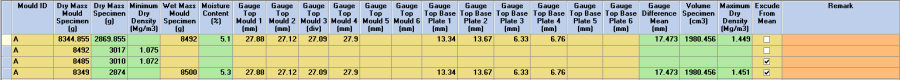

Lab-Comp Rel | Minimum Maximum Density

To calculate the Minimum and Maximum Density Values of a specimen, you must first select the standard from the Minimum_Density_Test_Method and Maximum_Density_Test_Method fields on the Minimum_Maximum_Density (upper) table that the specimen is being tested against. Fields are highlighted to assist you in entering the relevant data in the Minimum_Maximum_Density (upper) table for the selected test method.

Enter the test data in the data entry fields on the Minimum_Maximum_Density (lower) table for each test and when you change table or select save, the values will be calculated automatically and the result will be displayed in the calculated fields.

To calculate the minimum particle density, only enter the value in the Dry_Mass_Mould_Specimen field and the Mould_ID. If you enter data into the other data entry fields then the Maximum Dry Density field will be calculated.

It is not necessary to enter a value in all 6 Gauge_Top_Mould and Gauge_Top_Base_Plate fields. These fields require data in mm.

You may record multiple Minimum and Maximum test for the one specimen, and the Mean of each is recorded on the Minimum_Maximum_Density (upper) table. You may exclude a particular test from the mean by checking the Exclude_From_Mean check box.

Output

- Graphic Text Report | L CR MINIMUM MAXIMUM DENSITY